Many kinds of Auto Coating Machine to reach customers' requirements.

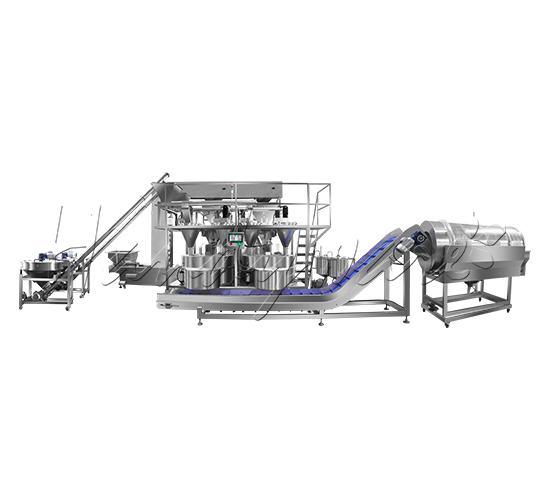

Auto Coating Machine ACM1200E

Processing:

1.There are two screw conveyors for two kinds of flour.And transport these flours into auto coating machine.

2.Z elevator to feed the peanuts into auto coating machine.

3.Syrup is fed into the coating via syrup pump.

4.Action in the coating pan.First flour falls into the action process,and then the secod flour falls

into auto coating pan before coating is finished.

5.The coated peanuts discharge to the conveyor and transport to the shifting system.

ADVANTAGES OF AUTO COATING MACHINE

Labour Cost Saving • Automatic, require initial set-up only.

• Save 1-2 person effort (compared to using conventional batch coating process)

Excellent End Product

• Consistent end product shape, size and quality, as process is automated

Flexible End Product • Suitable for coating on all kinds of peas and seeds (eg peanuts, green peas, sunflower seeds etc)

• May to add flavouring during coating, or apply seasoning after coating

Easy to use and Labour Cost Saving • Centralized touch screen control to manage end product formulation

• Saved formulation easily reusable

Top Quality • Manufactured using high quality stainless steel (304)

Easy Cleaning • Coating pan can be machine lifted to clean

• Peristaltic pump syrup tube easy to remove and clean. Pump does not contact syrup

Back to Automatic Coating Machine

Back to Automatic Coating Machine