2003

4600 m²

20 +

15 +

Handyware was established in the Philippines in 1968. Over the last 47 years Handyware Group has grown into a multi-national company with presences in many countries. Handyware (China) was established in 1993.

Handyware (China) Engineering is the food snack machine engineering arm of Handyware (China). It was established in 2003 and has an office/factory of 4,600 square meters at Foshan City in GuangDong Province of China. We synergize with our sister companies of seasoning and flavouring to provide the best snack food engineering solutions to our customers.

Handyware (China) Engineering designs and development food snacks processing lines. We aim to produce machines that are stable, high in quality, easy to operate and low operating cost and competitively priced. We relentlessly strive to improve on our machines base on customer needs:

(1) Food safety

(2) Stable and good quality

(3) Easy to use

(4) Low operating cost

(5) Competitive pricing

Thailand, Vietnam, Africa, Palestine, Jordan, Sudan and many others.

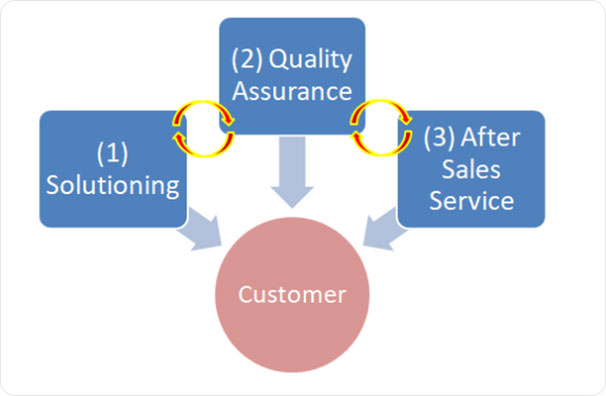

Customer Centric

Customer is the quintessence of Handyware Engineering business. We build upon a mentality of building machines focus on solving the problem of our customers or meet customer specific requirement, such as:

If you are looking to address either of the above, Handyware is a company for you. We look after your problems/requirements by focusing on 3 areas:

(1) Solutioning

Handyware Engineering adopts a customer-first mentality. We build upon a mentality of building machines focus on solving the problem of our customers or meet customer specific requirement, such as:

a. Expand current snack production lines

b. Plan to start new snack business

c. Looking to improve current snack production process

(A) Expand Current Snack Production Lines

Handyware’s team of engineers has 15 years of building processing system for potato chips, corn chips, pellets and other snacks product. We offer standard design of frying systems such as:

a. Fresh Potato Chips Processing Line

b. Fabricated Potato Chips Processing Line

c. Hexi, Triangle Shaped Corn/Potato Chips Processing Line

d. Potato Rings/Sticks Processing Line

e. Coated Peanuts Processing Line

f. Direct Puffed Snacks Frying System

g. Pellets Frying System

We have Customers from China, India, Pakistan, Bangladesh, Malaysia, Singapore, Philippines, Thailand, Vietnam, Africa, Palestine, Jordan, Sudan and many others.

These are some of the products from our customers :

(B) Plan To Start New Snack Business

No idea what to do? We have team of sales engineers that will propose snack business setup for you. From machines required, to raw material, seasoning requirement. Handyware has a strong team of food technologists specialize in food seasoning and flavoring. Synergizing with our strong team of machine engineers, we are able to offer one-stop food snack solution to our customers.

Handyware Group of companies possesses food engineering assets to develop end product for customers with the desired texture, taste and flavor. Handyware Group comprises of companies that develop food seasoning, flavors and machineries. Such unique synergy of assets enables Handyware to offer customers with a one-stop end solution for snack development. Either top down or bottom up approach, customers are able to receive the best snack food solutioning services from Handyware.

Handyware Group has more than 20 years of snacks product development for customers from China, Middle East, East Asia, South East Asian and African continent. By leveraging on such extensive experience, we are able to create innovative shaped and localized taste snacks to our customers.

(C) Looking to Improve Current Snack Production Process

Handyware continuously invest in product improvement to address customer feedbacks. In summary, the main concern of customer is food safety and low operating cost. We continuously improve our machines to address these concerns. By the choosing our machines, we are able to help improve the bottom line of our customer business. These are examples of case studies:

a. Automatic Coating Machine

b. Multipurpose Frying System

c. Continuous Frying System

(2) Quality Assurance

Our relentless approach towards quality assurance is key to our customer centric approach. We integrate CE requirement with our internal Quality Assurance Framework, covering standards on our entire manufacturing process. Besides safety, our QA Framework covers on functionality, durability, robustness and efficiency

(3) After Sales Service

Customers are concerned with the lifecycle of the machines. The overall machines ROI depend on the machines runtime and maintenance cost. Handyware focuses on building good quality machines in the first place to minimize maintenance cause. Proper handling and usage extends machine lifecycle. Hence Handyware emphasizes on user training and delivery of comprehensive user manual.

As part of after sales service, Handyware team of engineers provides quick response time to customer requests. For urgent matters, we respond immediately by phone. For email enquiry, we respond within 24 hours.